How we make our bongs and pipes

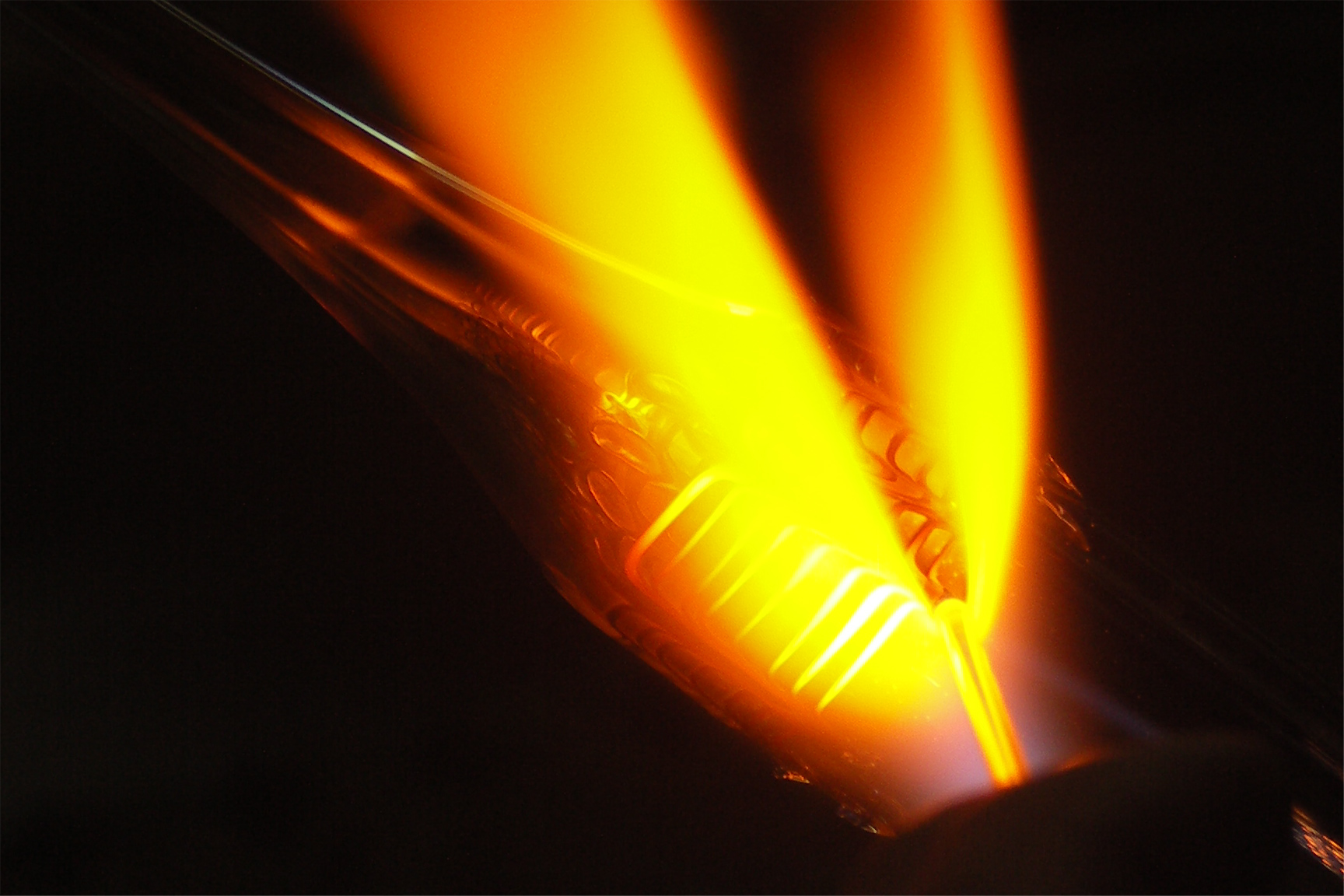

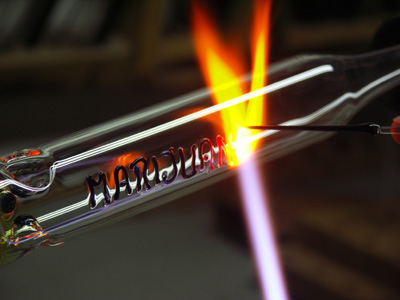

The first step is to put the small amount of silver or gold into the glass. We call this process "fuming" - "silver fuming" if using silver and "gold fuming" if using gold. After this the colors can be added on to the glass. This could vary and depends on the product. Some products are heavily fumed without additional colors, some are fumed less with lots of colors. The deposited colors are processed in several different ways and techniques. This creates the original colored patterns.

Glass blower is using his breath to blow out the bowls and to create the shape. The bigger bongs with double bowls are processed in parts. Once the basic shape is blown out, other surface glass decorations can be added. Eg. decoration of the water bong mouthpiece or slider holder. Also the holes for a slider and a carb are heated-up and blown out and ice catcher is made. After a while, when the bowls are little cooler, the rest of the material is cut off and the edges are softened and adjusted.

The cooling process of each glass piece is also important. The heavier the product is the more time is needed for its cooling. We use special ovens for slower cooling of the freshly made products, which makes the glass more durable. If the glass is cooled down too fast, it can crack in the future even if it is just resting on the shelf.